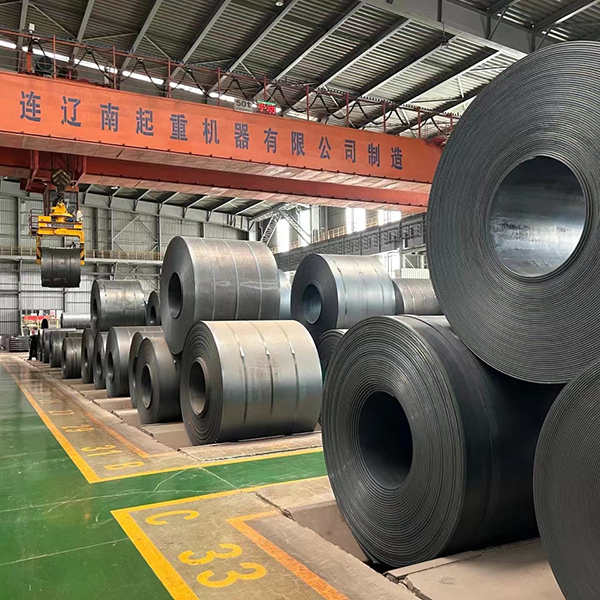

Carbon Steel Coil: Processing Methods and Wide - Ranging Uses

Carbon steel coils undergo various processing techniques to meet diverse industrial requirements, making them one of the most versatile materials in manufacturing and construction sectors.

Key processing methods include:

Slitting - Precision cutting of wide coils into narrower strips for specific applications

Leveling - Flattening coils to achieve uniform thickness and surface quality

Cut-to-Length - Custom sizing for immediate use in production processes

Galvanizing - Zinc coating application for enhanced corrosion resistance

Painting/Powder Coating - Surface treatments for aesthetic and protective purposes

These processed coils serve critical functions across multiple industries:

Automotive Manufacturing: Used for body panels, chassis components, and structural parts

Construction Sector: Transformed into roofing, wall cladding, and structural sections

Appliance Production: Forms the base material for refrigerators, washing machines, and ovens

Industrial Equipment: Fabricated into storage tanks, conveyor systems, and machinery housings

Advanced processing facilities now incorporate laser cutting and CNC punching technologies, enabling more complex shapes and tighter tolerances for specialized applications. The adaptability of carbon steel coils through these processing methods ensures their continued dominance in industrial material selection.

Comments

Post a Comment